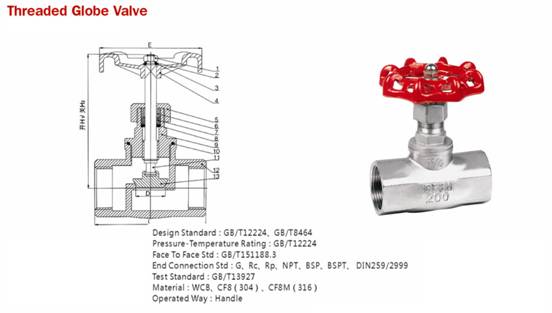

Description

Threaded globe valves, also known as screwed globe valves, are a type of KERUI valves used for regulating flow in a pipeline, widely used in such applications requiring throttling and frequent operation. They are often employed as regulation and cut-off device in such pipelines as tap water, sewage, construction, petroleum, metallurgy, energy system, etc.

Advantages

1. Compared with similar brands, our threaded globe valves have advantages of good sealing performance, small friction between sealing faces and long service life.

2. Screwed globe valves need small torque to open.

3. Valve body of KERUI valves is precisely cast.

4. Valve disc is processed by CNC technology.

Features

1. Compared with gate valves, globe valves are much simpler in structure. Thus they are easy to manufacture and maintain.

2. When starting or stopping threaded globe valves, the disc stroke is short. Therefore, its height is a bit lower than that of gate valves. But the structure length is longer.

4. Medium passway of screwed globe valves is quite zigzag, so the hydraulic resistance is large, leading to big power consumption.

5. When in use, the flow direction in globe valves is unidirectional and its flow direction can not be changed.

Attention

1. Read these instructions carefully. Failure to follow them could damage threaded globe valves or cause a hazardous condition.

2. Check the ratings given in the instructions and make sure the screwed globe valve is suitable for your application.

3. Installer must be a trained, experienced service technician.

4. After installation is complete, check out product operation as provided in these instructions.

5. Do not lift the valve by holding the stem.

6. Mount the valve with the flow arrow pointed in the direction of flow through the valve.

Parameters of Threaded Globe Valve

Main Parts & Materials

|

|

No.

|

Part Name

|

Material

|

QTY

|

|

1

|

Nut

|

304/316

|

1

|

|

2

|

Stem Washer

|

304/316

|

1

|

|

3

|

Name Plate

|

304/316

|

1

|

|

4

|

Handwheel

|

AL

|

1

|

|

5

|

Gland Ring

|

CF8/CF8M

|

1

|

|

6

|

Ring

|

304/316

|

1

|

|

7

|

Stem Packing

|

PTFE

|

1

|

|

8

|

Washer

|

304/316

|

1

|

|

9

|

Cap

|

CF8/CF8M

|

1

|

|

10

|

Gasket

|

PTFE

|

1

|

|

11

|

Stem

|

304/316

|

1

|

|

12

|

Body

|

CF8/CF8M

|

1

|

|

13

|

Disc

|

304/316

|

1

|

|

Size Range

|

DN

|

1/4’’-2’’(10-50mm)

|

|

Working Pressure

|

PN

|

200PSI(1.6-2.5Mpa)

|

|

Suitable Temperature

|

-29~150~350℃

|

|

Suitable Medium

|

CF8(304) Nitric Acid

|

CF8M Acetic Acid

|

Water Natural Gas Oil

|