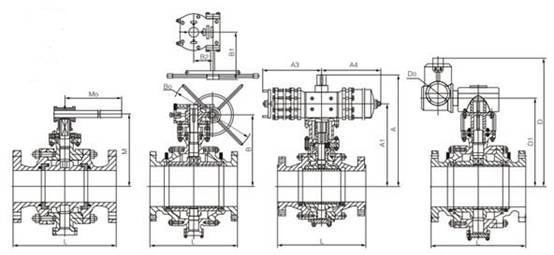

| Handle Operation | Worm Gear Operation | Pneumatic Operation | Electric Operation |

| A(G)TB1RF1 | A(G)3TB1RF1 | A(G)6TB1RF1 | A(G)9TB1RF1 |

| A(G)TB1BW1 | A(G)6TB1BW1 | A(G)6TB1BW1 | A(G)9TB1BW1 |

| No. | Parts | Materials | No. | Parts | Materials | |||||||

| Carbon Steel | Stainless Steel | Low Temperature Steel | Carbon Steel | Stainless Steel | Low Temperature Steel | |||||||

| 1 | Valve Body | ASTM A105 | A182 F304 | A350 LF2 | 19 | Grease Injection Valve | ASTM A105 | A182 F304 | A350 LF2 | |||

| 2 | Gasket | Flexible Graphite + SS | 20 | Upper Bushing | PTFE + CS | PTFE+SS | PTFE+SS | |||||

| 3 | Bleeder Valve | ASTM A105 | A182 F304 | A350 LF2 | 21 | Valve Stem | A182 F6a | A182 F304 | A182 F304 | |||

| 4 | Bottom Cap | ASTM A105 | A182 F304 | A350 LF2 | 22 | Flat Bushing | PTFE + CS | PTFE+SS | PTFE+SS | |||

| 5 | Bolt | A193 B7 | A193 B8 | A320 L7 | 23 | Yoke | A216 WCB | |||||

| 6 | Gasket | Flexible Graphite + SS | 24 | Adapter Sleeve | ANSI 1025 | |||||||

| 7 | O-ring | Fluororubber | 25 | Bolt | A193 B7 | |||||||

| 8 | Lower Bushing | PTFE + CS | PTFE + SS | PTFE + SS | 26 | O-ring | Fluororubber | |||||

| 9 | Ball |

ASTM A105+ENP |

A182 F304 | A182 F304 | 27 | O-ring | Fluororubber | |||||

| 10 | Flange Gasket | Flexible Graphite + SS | 28 | Gasket | Flexible Graphite + SS | |||||||

| 11 | O-ring | Fluororubber | 29 | Upper Valve Seat | ASTM A105 | A182 F304 | A350 LF2 | |||||

| 12 | Firewall | Flexible Graphite | 30 | Locating Pin | A182 F6a | |||||||

| 13 | Seal Ring | PTFE, NYLON, PEEK, MOLON, PCTFE | 31 | Bolt | A193 B7 | |||||||

| 14 | Valve Seat |

ASTM A105 + ENP |

A182 F304 | A182 F304 | 32 | Worm Screw and Worm Gear | / | |||||

| 15 | Spring | Inconel600 | 33 | Grease Injection Valve | ASTM A105 | A182 F304 | A350 LF2 | |||||

| 16 | Bolt | A193 B7 | A193 B8 | A320 L7 |

PS: 1) Sealing materials should be chosen according to the temperature and pressure of media. 2. Besides those materials listed above, we can use materials that customers require. |

|||||||

| 17 | Nut | A194 2H | A194 8 | A194 7 | ||||||||

| 18 | Bonnet | ASTM A105 | A182 F304 | A350 LF2 | ||||||||

Tag: Threaded Y Type Strainers | Y Type Threaded Strainer | China Pipeline Strainer Manufacturer | Threaded Type Y Strainer

Tag: Threaded Globe Valves | Screwed Globe Valve | KERUI Valve | Thread Stainless Steel Globe Valve