Introduction

Check valve, also known as non return valve, reflux valve, one-way valve or counterbalance valve, opens and closes automatically depending on media flowing pressure. Butt weld forged steel check valve is mainly composed of include valve body, disc, bonnet and gasket. We have swing check valve and lift check valve.

Application

This type of forged steel valve is used to prevent reverse flow and leakage of medium, such as fluid, gas, etc. It is also applied to stop reversal of pump and driving motor. Butt weld forged steel check valve can be widely applied as fluid regulating and intercepting equipment in tap water, sewage, construction, petroleum, chemical, food, medicine, textile, electric power, shipbuilding, metallurgy, and other pipeline systems.

Advantages

1. Sealing material can be selected according to medium so as to enhance reflux valve’s sealing property and wear resistance.

2. It needs small twisting force to close butt weld forged steel check valve.

3. Friction between sealing surfaces is small.

4. The disc sealing surface can be customized. Customer can choose sealing materials like deposited metal material or inset non-metallic material according to requirement.

5. All our check valves are guaranteed for 18 months. Lifelong technology consultancy service is available for our products.

Features of Butt Weld Forged Steel Check Valve

1. Precision casting and CNC processing technology is adopted for making valve body.

2. Disc restrainer is designed to prevent that the open position of disc is too high to be shut down.

3. High strength solid pin is installed precisely, which assures excellent performance and long serving life.

4. Rocker is with high strength and flexibility for disc closing.

5. Disc of butt weld forged steel check valve is with high strength and stiffness.

6. Sealing performance of the forged steel valve is good.

7. Two times shot blasting processing of valve surface make this forged steel valve look fine and smooth.

8. Full port is one of this reflux valve’s main features.

Classification of Butt Weld Forged Steel Check Valve

1. According to Pressure: CLASS150/300/600

2. According to Bonnet: Bolted Bonnet or Welded Bonnet

3. Swing Type or Lift Type

4. According to End: Flange End or Butt Weld End

Pressure: CLASS150~600

1. Bolted Bonnet/Welded Bonnet

2. Full Port

3. Swing or Lift Type

4. Flange Ends or Butt-Welding Ends

Technical Specification

|

Design Standard

|

ASME B16.34/BS5352

|

|

Pressure-Temperature Rating

|

ASME B16.34

|

|

Face-Face

|

ASME B16.10

|

|

Flange Ends

|

ASME B16.5

|

|

Buttwelding Ends

|

ASME B16.25

|

|

Inspection & Test

|

API598

|

Material List for Main Parts of Butt Weld Forged Steel Check Valve

|

No.

|

Part name

|

ASTM

|

|

Carbon Steel

|

Tailess Steel

|

Alloy Steel

|

|

1

|

Body

|

A105

|

LF2/LF3

|

A182 F304

|

A182 F11/F22

|

|

2

|

Seat

|

A182F6a

|

A182F6a

|

A182 F304

|

A182 F11/F22

|

|

3

|

Disc/Ball

|

A182F6a

|

A182F6a

|

A182 F304

|

A182F6a

|

|

4

|

Pin

|

A276-410

|

A276-410

|

A276-410

|

A276-410

|

|

5

|

Spring

|

Si.Mn Alloy Steel

|

Stainless Steel

|

Cr.V Alloy Steel

|

|

6

|

Gasket

|

Graphite+304

|

|

7

|

Bonnet

|

A105

|

LF2/LF3

|

A182 F304

|

A182 F11/F22

|

|

8

|

Bolt

|

A193 B7

|

A320L7

|

A193 B8

|

A193 B16

|

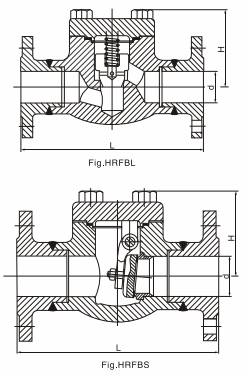

Main Dimensions & Weight of Butt Weld Forged Steel Check Valve

|

Pressure

|

Size

|

Main Dimension of Valve Reflux Valve

|

|

|

mm

|

in.

|

d

|

LRF

|

LBW

|

H

|

Weight(kg)

|

|

Lift type

|

Swing type

|

|

CLASS150

|

15

|

1/2

|

13

|

105

|

105

|

61

|

61

|

3.4

|

|

20

|

3/4

|

18

|

117

|

117

|

78

|

78

|

4.4

|

|

25

|

1

|

24

|

127

|

127

|

84

|

84

|

8.2

|

|

32

|

1-1/4

|

29

|

140

|

140

|

103

|

101

|

8.9

|

|

40

|

1-1/2

|

36.5

|

165

|

165

|

118

|

120

|

12.0

|

|

50

|

2

|

46.5

|

203

|

203

|

130

|

133

|

14.3

|

|

CLASS300

|

15

|

1/2

|

13

|

152

|

152

|

61

|

61

|

3.7

|

|

20

|

3/4

|

18

|

178

|

178

|

78

|

78

|

4.8

|

|

25

|

1

|

24

|

203

|

203

|

84

|

84

|

8.8

|

|

32

|

1-1/4

|

29

|

216

|

216

|

103

|

101

|

9.6

|

|

40

|

1-1/2

|

36.5

|

229

|

229

|

118

|

120

|

13.7

|

|

50

|

2

|

46.5

|

267

|

267

|

130

|

133

|

17.8

|

|

CLASS600

|

15

|

1/2

|

13

|

165

|

165

|

61

|

61

|

4.0

|

|

20

|

3/4

|

18

|

190

|

190

|

78

|

78

|

5.8

|

|

25

|

1

|

24

|

216

|

216

|

84

|

84

|

9.5

|

|

32

|

1-1/4

|

29

|

229

|

229

|

103

|

101

|

10.4

|

|

40

|

1-1/2

|

36.5

|

241

|

241

|

118

|

120

|

15.6

|

|

50

|

2

|

46.5

|

292

|

292

|

130

|

133

|

24.5

|

Note: H means the height when reflux valve is fully opened.

Malfunction, Reason and Solution

|

Malfunction

|

Disc Breakage

|

Medium Backflow

|

|

Reason

|

The disc beat the valve seat frequently. Some disc valves which are made of brittle materials (such as cast iron, brass, etc.) will be easily broken.

|

1. Sealing surface is damaged. 2. Impurities are sandwiched between sealing surfaces.

|

|

Solution

|

Applying ductile materials to manufacturer valve disc

|

Repairing the sealing surface or cleaning impurities

|

Working Principle

Butt weld forged steel check valve allows medium to flow through it in only one direction, and it prevents reverse direction flow. Disc of reflux valve will open under the pressure of forward flow fluid. When fluid flows in reverse direction, the disc will be closed by fluid pressure and dead weight so as to cut off the flow.

Payment, Package and Transportation

1. Butt weld forged steel check valves can be paid by T/T, D/P, D/A, L/C, and so on.

2. Standard exporting wooden cases are employed for packaging.

3. Products are transported by air, sea or railway.