Description

DIN three-way flanged floating ball valve has distinct characteristics like small volume, reliable sealing performance, simple structure, convenient maintenance and high corrosion resistance. This three-way ball valve is used for cutting off, distributing and altering the flowing direction of medium, widely applied in water, oil, natural gas, weak corrosive liquid, etc.

Advantages

1. Our company attaches much importance on technology renovation, process improvement, structure optimization and quality improvement. Moreover, three-way ball valves are strictly inspected before into storage, thus ensuring quality.

2. KERUI has excellent after-sale service system, providing optimal and timely service, and has been winning widespread recognition and praise.

3. Our DIN valves are guaranteed within the first 18 months.

Features

1. The sealing materials of this three-way ball valve all adopt standard PTFE and PPL, carbon fiber, etc. They are formed and cooled under high-temperature pressing, then processed by digital controlled lathe. In this way, the sealing performance and wear resistance is guaranteed, leading a longer service life.

2. The ball of this DIN valve is of floating type, therefore, under the function of pressure, it can generate a certain amount of displacement and press tightly on the sealing surface of exit end, guaranteeing excellent sealing performance of exit end.

Parameters of DIN Three-Way Ball Valve

| Model | Q45F-16C | Q45F-25C | Q45F-40C | Q45F-16P | Q45F-25P | Q45F-40P | |

| Working Pressure (℃) | 1.6 | 2.5 | 4.0 | 1.6 | 2.5 | 4.0 | |

| Applicable Temperature (℃) | ≤150 | ||||||

| Medium | Water, Oil, Steam | Weak Corrosive Medium | |||||

| Materials | Valve Body | Carbon Steel Casting | CrNiTi Stainless Steel | ||||

| Ball/Stem | 2Cr13 | CrNiTi Stainless Steel | |||||

| Seal Ring | Reinforced PTFE | ||||||

| Packing | PTFE | ||||||

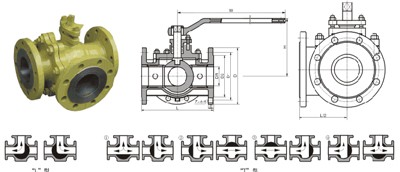

Structure of DIN Three-Way Ball Valve

Parameters

| Nominal Diameter | Main Shape Sizes and Connection Sizes | |||||||

| L | D | D1 | D2 | b | Z-d | H | W | |

| Q44F-16C Q44f-16P Q644F-16C Q644F-16P Q944F-16P Q45F-16C Q45F-16P Q645F-16C Q645F-16P Q945F-16C Q945f-16P | ||||||||

| 15 | 108 | 95 | 65 | 45 | 14 | 414 | 95 | 140 |

| 20 | 117 | 105 | 75 | 55 | 14 | 414 | 105 | 164 |

| 25 | 127 | 115 | 85 | 65 | 14 | 414 | 113 | 180 |

| 32 | 140 | 135 | 100 | 78 | 16 | 418 | 135 | 250 |

| 40 | 165 | 145 | 110 | 85 | 16 | 418 | 142 | 300 |

| 50 | 178 | 160 | 125 | 100 | 16 | 418 | 154 | 350 |

| 65 | 191 | 180 | 145 | 120 | 18 | 818 | 175 | 350 |

| 80 | 203 | 195 | 160 | 135 | 20 | 818 | 190 | 400 |

| 100 | 229 | 215 | 180 | 155 | 20 | 818 | 225 | 500 |

| 125 | 356 | 245 | 210 | 185 | 22 | 818 | 245 | 600 |

| 150 | 394 | 280 | 240 | 210 | 24 | 823 | 265 | 800 |

| 200 | 457 | 335 | 295 | 265 | 26 | 1223 | 305 | 800 |

| 250 | 533 | 405 | 355 | 320 | 30 | 1225 | 370 | 1300 |

Tag: Threaded Globe Valves | Screwed Globe Valve | KERUI Valve | Thread Stainless Steel Globe Valve

Tag: Threaded Y Type Strainers | Y Type Threaded Strainer | China Pipeline Strainer Manufacturer | Threaded Type Y Strainer