Description

Globe valve, also named stop valve, is mainly made up of valve body, disc, shaft pin and stem. Socket weld forged steel globe valve is a valve with closure member (disc) moving along with the center line with valve seat. Since it has relative short opening and closing stroke, this valve is very suitable for cutting off and regulating medium flow.

Advantages

1. Friction is small between sealing surfaces.

2. It needs small torsion to open the valve.

3. CNC processing is applied on valve disc.

4. Precision casting technology is adopted to manufacture valve body.

5. Socket weld forged steel globe valve is featured by fine sealing performance and long service time.

6. Two times shot blasting makes exquisite outward appearance of this socket weld stop valve.

7. 18 months warranty and lifetime technology service are offered for our products.

8. All our products have passed CE and JB/T9092 certification.

Applications

Our socket weld forged steel globe valve is widely applied on tap water, sewage, building, petroleum, chemical, food, medicine, textile, electricity, ship, metallurgy, energy and other pipeline systems.

1. This socket welded valve is suitable for high temperature and pressure medium pipelines and devices, such as petrochemical pipelines systems in thermal power plants and nuclear power stations.

2. It is applicable for pipelines with small requirement on flow resistance, that is, it is suitable for pipelines where too much consideration of pressure loss is not necessary.

3. Low requirement on regulating precision and small diameter (nominal diameter ≤ 50 mm) pipeline should employ socket weld forged steel globe valve.

4. In compound industry, chemical fertilizer production should utilize high pressure angle type globe valve.

5. In alumina production process, straight flow globe valve (with cemented carbide sealing and removable valve seat) should be employed on easy coking pipeline in desilication workshop.

6. This type of stop valve is extensively used on water and heat supply engineering in urban construction.

Classifications

1. According to channel direction of the valve, it can be classified into straight through type/straight flow type/angle type/plunger type globe valve.

2. According to the location of the thread on valve stem, it can be divided into upper/lower threaded stem globe valve.

3. According to application, it can be classified into heating jacket/forged steel/oxygen dedicated/bellows/low temperature globe valve (stop valve).

Pressure: CLASS900-1500 PN16.0~26.0

1. Bolted Bonnet / Welded Bonnet Pressure Sealed Bonnet

2. Full Port

3. General or Needle Type Disc

4. Treaded Ends or SW Ends

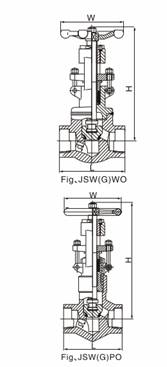

Technical Specification of Socket Weld Forged Steel Globe Valve

|

Technical Specification

|

ASME/API

|

GB/JB

|

|

Design Standard

|

API602

|

GB/T7746

|

|

Pressure-Temperature Rating

|

ASME B16.34

|

GB/T12224

|

|

Face-Face

|

Factory Standard

|

GB/T7746

|

|

Socket-Welded Ends

|

ASME B16.11

|

GB/T1751

|

|

Threaded Ends

|

ASME B1.20.1

|

GB/T306

|

|

Inspection & Test

|

API598

|

JB/T9092

|

Material List for Main Parts of Forged Steel Globe Valve

|

No.

|

Part Name

|

ASTM

|

|

Carbon Steel

|

Tailess Steel

|

Alloy Steel

|

|

1

|

Body

|

A105

|

LF2/LF3

|

A182 F304

|

A182 F11/F22

|

|

2

|

Disc

|

A182F6a

|

A182F6a

|

A182 F304

|

A182 F6a

|

|

3

|

Stem

|

A276-410

|

A276-410

|

A276-304

|

A276-410

|

|

4

|

Gasket

|

Graphite+304

|

|

5

|

Sealing Ring

|

Graphite

|

|

6

|

Yoke

|

A216-WCB

|

A216-WCB

|

A351 CF8

|

A216-WCB

|

|

7

|

Bonnet

|

A105

|

LF2/LF3

|

A182 F304

|

A182 F11/F22

|

|

8

|

Gland

|

A216-WCB

|

A216-WCB

|

A351 CF8

|

A216-WCB

|

|

9

|

Bolt

|

A193 B7

|

A320L7

|

A193 B8

|

A193 B16

|

|

10

|

Packing

|

Graphite

|

|

11

|

Stem Bushing

|

A276-410

|

A276-410

|

A276-304

|

A276-410

|

|

12

|

Gland

|

A216-WCB

|

A216-WCB

|

A351 CF8

|

A216-WCB

|

|

13

|

Eye Blot

|

A193 B7

|

A320 L7

|

A193 B8

|

A193 B7

|

|

14

|

Stem Nut

|

A276-410

|

|

15

|

Handwheel

|

A197 or A47-32510

|

Main Dimensions & Weight of Socket Weld Forged Steel Globe Valve

|

Pressure

|

Size

|

Main Dimension of Stop Valve

|

Weight(kg)

|

|

mm

|

in.

|

D

|

L

|

H

|

W

|

|

BB/WB

|

PB

|

BB/WB

|

PB

|

BB/WB

|

PB

|

BB/WB

|

PB

|

WB

|

PB

|

|

CLASS900 PN16.0

|

8

|

1/4

|

7

|

-

|

111

|

-

|

207

|

-

|

100

|

-

|

2.4

|

-

|

|

10

|

3/8

|

10

|

-

|

111

|

-

|

207

|

-

|

100

|

-

|

2.2

|

-

|

|

15

|

1/2

|

13

|

13

|

111

|

140

|

207

|

207

|

100

|

125

|

2.0

|

11.2

|

|

20

|

3/4

|

18

|

18

|

130

|

140

|

240

|

207

|

125

|

125

|

3.8

|

10.5

|

|

25

|

1

|

24

|

24

|

152

|

140

|

258

|

240

|

160

|

160

|

4.2

|

10.1

|

|

32

|

1-1/4

|

29

|

29

|

172

|

178

|

290

|

258

|

160

|

160

|

8.0

|

21.0

|

|

40

|

1-1/2

|

36.5

|

36.5

|

220

|

178

|

337

|

290

|

180

|

180

|

13.2

|

19.6

|

|

50

|

2

|

46.5

|

46.5

|

235

|

216

|

354

|

337

|

240

|

240

|

16.8

|

40.4

|

|

CLASS1500 PN26.0

|

8

|

1/4

|

7

|

-

|

111

|

-

|

207

|

-

|

100

|

-

|

2.4

|

-

|

|

10

|

3/8

|

10

|

-

|

111

|

-

|

207

|

-

|

100

|

-

|

2.2

|

-

|

|

15

|

1/2

|

13

|

13

|

111

|

140

|

207

|

207

|

100

|

125

|

2.0

|

11.2

|

|

20

|

3/4

|

18

|

18

|

130

|

140

|

240

|

207

|

125

|

125

|

3.8

|

10.5

|

|

25

|

1

|

24

|

24

|

152

|

140

|

258

|

240

|

160

|

160

|

4.2

|

10.1

|

|

32

|

1-1/4

|

29

|

29

|

172

|

178

|

290

|

258

|

160

|

160

|

8.0

|

21.0

|

|

40

|

1-1/2

|

36.5

|

36.5

|

220

|

178

|

337

|

290

|

180

|

180

|

13.2

|

19.6

|

|

50

|

2

|

46.5

|

46.5

|

235

|

216

|

354

|

337

|

240

|

240

|

16.8

|

40.4

|

Note: H means the height when valve is fully opened.